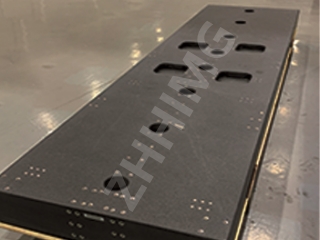

Granite has been commonly used in the semiconductor industry for the manufacturing of precision equipment, including wafer processing equipment. This is due to the material's excellent properties such as high stiffness, low thermal expansion, and high vibration damping. It provides a stable and flat surface, which is important in the production of tiny electronic circuits on wafers.

When using granite in wafer processing equipment, it is important to take proper precautions to ensure maximum efficiency and longevity. Here are some tips for using and maintaining granite properly.

1. Proper handling and installation

Granite is an extremely heavy and brittle material that requires proper handling and installation. It is crucial to make sure that the surface is leveled before installation. Any unevenness can lead to damage to the equipment, which can affect the quality of the wafers produced. Granite should be handled with care and should be transported and installed with the aid of specialized equipment.

2. Regular cleaning

Wafer processing equipment that uses granite needs to be cleaned regularly to prevent the accumulation of debris and dirt on the surface. The accumulation of debris can cause scratches or lead to the formation of cracks, which can affect the quality of the wafers produced. A soft cloth and a mild soap solution can be sufficient for cleaning granite surfaces. Harsh detergents and chemicals should be avoided as they can damage the surface.

3. Preventive maintenance

Preventive maintenance is essential to ensure that the wafer processing equipment functions optimally. The equipment and the granite surface should be inspected regularly, and any signs of damage should be addressed immediately. This can help detect problems early and prevent them from emerging into bigger problems that are more costly to repair.

4. Avoid thermal cycling

Granite is sensitive to temperature changes, and thermal cycling should be avoided. Rapid changes in temperature can cause granite to expand and contract, leading to cracking or warping of the surface. Maintaining a stable temperature in the processing room can help prevent this from occurring. Additionally, it is important to avoid placing hot objects on the granite surface to prevent thermal shock.

In conclusion, granite is a commonly used material in wafer processing equipment due to its superior properties that contribute to the production of high-quality wafers. To ensure maximum efficiency and longevity, proper handling, regular cleaning, preventive maintenance, and avoiding thermal cycling are crucial. These practices can help keep the equipment in excellent condition, resulting in optimal productivity and high-quality wafers.

Post time: Dec-27-2023