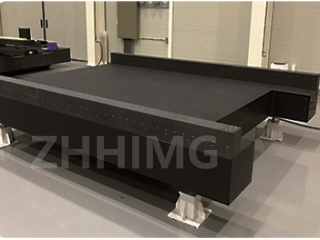

Granite machine bases are an integral component in many Automation Technology products. They provide a stable and solid foundation for machines to operate on and ensure precision and accuracy in their performance. However, like any other equipment, they require proper use and maintenance to function optimally and prolong their lifespan.

Here are some tips on how to use and maintain granite machine bases for Automation Technology products:

1. Proper installation: Ensure that the machine base is installed correctly. The base should have a level and stable surface to prevent any distortion during use. It is essential to follow the manufacturer's instructions for installation and leveling.

2. Regular cleaning: Regular cleaning is critical to maintain the granite machine base's cleanliness and prevent accumulation of dirt or debris. It is advisable to use a soft brush or cloth to wipe the surface particles. Avoid harsh chemicals that may corrode or scratch the surface.

3. Regular inspection: Inspect the machine base regularly for any visible signs of wear or damage, such as cracks or chips. If you find any such damage, notify a qualified technician to repair the base or replace it with a new one.

4. Monitor temperature: Granite machine bases are sensitive to extreme temperature variations. Avoid exposing the base to extreme temperatures to prevent distortion or warping. Maintain a constant temperature in the environment, and use a cooling system if necessary.

5. Avoid excessive pressure: Never overload the machine base with excessive weight or pressure. Overloading may lead to cracks, chips, or other damage. Always adhere to the recommended load limits provided by the manufacturer.

6. Lubrication: Lubrication is necessary to keep the granite machine base functioning optimally. Check the manufacturer's recommendations for lubrication or consult an expert technician. Make sure to follow the recommended schedule for lubrication.

7. Regular calibration: Calibration is essential to ensure that the machine base and components operate within the required tolerance. Regular calibration will ensure accurate performance and prolong the machine base's life span.

In conclusion, granite machine bases are essential components in Automation Technology products. Proper use and regular maintenance of these bases will ensure their longevity and optimal performance. Follow the tips provided above to maintain the machine base for Automation Technology products, and you will enjoy excellent service from them.

Post time: Jan-03-2024