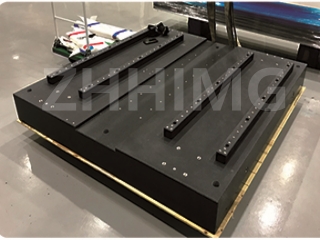

Granite machine base for Universal length measuring instrument products is an important component that provides the perfect foundation for precise measurements. Granite, known for its high strength and durability, is an ideal material for machine bases, particularly for industries that require meticulous measurements such as mechanical engineering, aerospace, and automotive. These machine bases offer high stability and thermal stability, ensuring precision in the measurements. Here are some essential guidelines for using and maintaining granite machine bases for Universal length measuring instrument products.

1. Installation Guidelines

It is essential to ensure that the granite machine base is installed correctly. The base must be levelled and secured to the floor before the Universal length measuring instrument is placed on it. The machine base must be placed in an area free from vibration to assure accurate measurements.

2. Cleaning and Maintenance

The granite machine base for Universal length measuring instrument products must be cleaned and maintained regularly to maintain optimal performance. Avoid using harsh cleaning agents that can damage the granite surface. Instead, a mild soap or cleaning solution should be used to clean the machine base's surface. Cleaning should be done at regular intervals depending on the frequency of use.

3. Avoid Excessive Weight and Impacts

Granite machine bases offer high stability, but they have their limits. It is important to avoid placing excessive weights on the machine base, as this can lead to warping or cracking of the granite surface. Similarly, impacts on the machine base must be avoided as they can also cause damage.

4. Temperature Control

Granite machine bases are sensitive to temperature variations. It is important to ensure that the temperature in the room where the machine base is installed is controlled. Avoid placing the machine base in areas where there are temperature fluctuations, such as areas near windows or skylights.

5. Lubrication

The Universal length measuring instrument placed on the granite machine base requires smooth movements. Lubrication should be done regularly to ensure that the machine's moving parts work smoothly without friction. However, it is crucial to avoid over-lubrication, as it can cause oil to accumulate on the machine base, creating a risk of contamination.

6. Regular Calibration

Calibration is an essential aspect of maintaining accurate measurements. Regular calibration checks must be done to ensure that the measurements are consistent and precise. The frequency of calibration depends on the frequency of use, but most industries require calibration checks to be done at least once a year.

In Conclusion

The granite machine base for Universal length measuring instrument products is a crucial element that requires proper care and maintenance to achieve optimal performance. The guidelines mentioned above are essential for anyone looking to use and maintain their granite machine base properly. With proper installation, regular cleaning and maintenance, temperature control, sufficient lubrication, and regular calibration checks, users can be assured that their Universal length measuring instrument will deliver accurate and consistent results for years to come.

Post time: Jan-22-2024