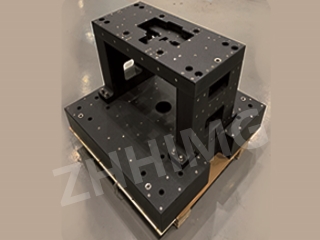

Granite assembly is a crucial component in semiconductor manufacturing processes. The assembly is typically used as a base material for the construction of precision equipment used in the production of semiconductors. This is due to the distinct advantages and properties of granite, which make it an ideal material for this application.

Granite is preferred in semiconductor manufacturing due to its high stiffness, thermal stability, excellent dimensional stability, and low coefficient of thermal expansion. These properties make granite Assembly an ideal material for precision applications that require high levels of accuracy, such as semiconductor wafer processing equipment.

In semiconductor manufacturing processes, the use of granite assembly ensures precise alignment and positioning of various equipment components, such as wafers, vacuum chambers, and processing tools. This is essential in order to achieve the necessary level of accuracy required in semiconductor fabrication.

Another important advantage of granite assembly is its ability to maintain its shape and size over a wide range of temperatures. This is critical in the semiconductor industry, where high temperatures are used in various stages of device fabrication.

Furthermore, granite assembly provides excellent resistance to wear and tear, making it a durable and long-lasting material for equipment components.

In conclusion, the use of granite assembly in semiconductor manufacturing processes is essential for ensuring the production of high-quality semiconductors. Its unique properties, such as high stiffness, thermal stability, and dimensional stability, make it an ideal choice for precision applications. Furthermore, the durability and resistance to wear and tear ensure that equipment components made from granite assembly will last for extended periods, reducing maintenance costs. Therefore, manufacturers should continue to utilize this material to ensure the highest levels of accuracy and reliability in their semiconductor manufacturing processes.

Post time: Dec-06-2023