Granite is a popular choice for industrial computed tomography (CT) machines due to its excellent mechanical properties and stability. It is a hard and durable material that can withstand the vibrations and other stresses that arise during a CT scan. In this article, we will explore how to use granite base for industrial computed tomography.

First, let's understand what industrial CT is and how it works. Industrial CT is a nondestructive testing method that uses X-rays to inspect the internal structure of objects. The CT scanner takes a series of X-ray images from different angles, which are then reconstructed into a 3D image by a computer. This enables the user to see inside the object and identify any defects or anomalies.

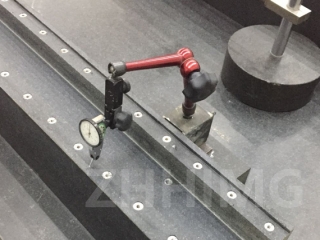

The granite base plays a crucial role in the performance of the CT machine. It provides a stable platform for the X-ray source and detector to rotate around the object being scanned. This is important because any movement or vibration during the scanning process can cause blurring or distortion of the images.

Here are some tips on using granite base for industrial CT:

1. Choose the right type of granite - There are different grades of granite available, and it is important to choose the right one for your CT machine. The granite should have low thermal expansion coefficient, high dimensional stability, and good rigidity. At the same time, it should be easy to machine and polish.

2. Optimize the design of the granite base - The geometry and dimensions of the granite base should be optimized to achieve maximum stability and accuracy. The base should be designed to minimize vibration and deformation during the scanning process. The base should also be large enough to accommodate the object being scanned.

3. Use high-quality mounting systems - The X-ray source and detector should be securely mounted on the granite base using high-quality mounting systems. This will ensure that they remain stable during the scanning process and do not move or vibrate.

4. Maintain the granite base regularly - Regular maintenance of the granite base is important to ensure its performance and longevity. The base should be cleaned and inspected regularly to identify any signs of wear or damage.

In conclusion, using granite base for industrial CT is a smart choice for achieving high-quality and accurate results. By choosing the right type of granite, optimizing the design of the base, using high-quality mounting systems, and maintaining the base regularly, you can ensure the longevity and best performance of your CT machine.

Post time: Dec-08-2023