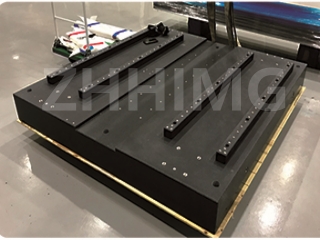

Granite is a popular material for the base of laser processing machines due to its excellent stability, durability, and resistance to vibration. Granite has a higher density and lower porosity than most metals, which makes it less susceptible to thermal expansion and contraction, ensuring greater accuracy and stability during laser processing. In this article, we will discuss how to use granite base for laser processing in detail.

1. Choosing the right type of granite

When selecting a granite base for laser processing, it is essential to choose the right type of granite with the correct characteristics for the intended use. Factors to consider include:

- Porosity - select granite with a low porosity to avoid oil, dust, and moisture infiltration.

- Hardness - choose a hard granite type such as Black Galaxy or Absolute Black, which have a Mohs hardness of between 6 and 7, making them resistant to wear and tear from regular use.

- Thermal stability - look for granite types with a high thermal coefficient that provide excellent thermal stability during laser processing.

2. Ensuring the granite base is levelled and stable

Laser processing equipment is highly sensitive, and any slight deviation from a level surface can cause inaccuracies in the final product. Therefore, it is vital to ensure that the granite base on which the equipment is mounted is levelled and stable. This can be achieved by using precision levelling equipment to check and adjust the base's levelness and then fixing it in place using bolts or epoxy.

3. Maintaining the granite base's cleanliness and humidity

Maintaining the cleanliness and humidity of the granite base is crucial to ensuring its longevity and performance. Granite is susceptible to staining, and any residue or dirt on the surface can negatively affect laser processing equipment's performance. Therefore, it is essential to keep the base clean and free of debris by following the manufacturer's recommended cleaning procedures.

Additionally, granite is sensitive to changes in humidity, and prolonged exposure to high humidity levels can cause it to expand. This can cause equipment alignment issues, leading to product accuracy problems. To avoid these issues, it is recommended to maintain humidity levels at around 50% while storing the equipment and the granite base.

4. Ensuring adequate ventilation for the granite base

During laser processing, the equipment generates heat that must be dissipated. Therefore, the granite base must have adequate ventilation to prevent overheating. This can be achieved through the installation of ventilation fans or ducts that direct hot air away from the equipment.

In conclusion, using a granite base for laser processing is an excellent choice due to its superior durability, stability and resistance to vibration. However, it is crucial to choose the right type of granite, ensure the base is levelled and stable, maintain the cleanliness and humidity levels, and provide adequate ventilation to ensure optimal performance. With proper care and maintenance, a granite base can provide a stable and durable foundation for laser processing equipment for many years to come.

Post time: Nov-10-2023