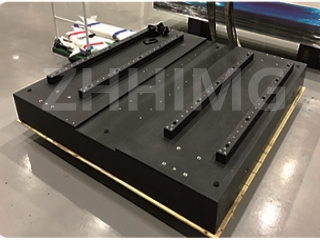

Granite base has become one of the most popular materials to build precision assembly devices as it provides a sturdy and stable platform. The use of granite has proven to be an incredible material that can withstand temperature changes, pressure and overall wear-and-tear while still maintaining its shape. In this article, we will explore how to use granite base for precision assembly devices.

Accuracy

Granite has an exceptional property that allows it to maintain its dimensional accuracy even when exposed to environmental changes such as temperature and humidity. This makes it an ideal material for precision assembly devices that need to work with tight tolerances. Granite base can be used as the foundation of a precision assembly device, providing a stable and reliable platform to work with.

Precision

Granite is a naturally occurring material that is formed by the slow crystallization of magma deep within the earth's crust. As a result, it has a uniform structure, which means that it can be precisely machined to create flat, smooth surfaces. This makes it an excellent choice for precision assembly devices that need to have a smooth working surface.

Stability

Granite base provides excellent stability for precision assembly devices. It is a dense material that has a very low coefficient of thermal expansion, which means that it will not expand or contract with changes in temperature. This results in a stable surface that does not warp or bend, providing consistent results. Additionally, it can dampen vibrations and reduce noise, ensuring that precision assembly devices perform their task without being influenced by external factors.

Durability

Granite is an incredibly durable material, and hence, it is an excellent choice for precision assembly devices. It can withstand intense pressure and has a high resistance to wear and tear. The hardness of granite is only surpassed by diamond, which means it can withstand heavy usage without being damaged. Additionally, it is resistant to corrosion, which makes it ideal for use in precision assembly devices that need to work with chemicals or liquids.

Final Thoughts

The use of granite base for precision assembly devices has shown to be an excellent choice. Its properties of accuracy, precision, stability, and durability make it an ideal material for creating the foundation for such devices. Granite base provides a sturdy and stable platform, which is vital for precision assembly devices to function at their highest capacity. Therefore, it is essential to consider the use of granite bases when designing and building precision assembly devices.

Post time: Nov-21-2023