Granite is a naturally occurring material that is widely used in the manufacturing industry for machine bases. Granite machine bases are known for their high-stability, durability, and excellent vibration damping properties, which make them an ideal choice for high-precision machinery applications. One such application where granite machine bases are commonly used is LCD panel inspection devices, which are used to detect and analyze defects in LCD panels before they are assembled into electronic devices.

The design and construction of an LCD panel inspection device require a high level of accuracy, stability, and precision. Any vibration or movement during panel inspection can cause measurement errors, which can lead to inaccurate results and costly production errors. The use of a granite machine base can help to eliminate these issues and improve the overall performance and accuracy of the inspection device. Here are some ways to use granite machine bases effectively for an LCD panel inspection device:

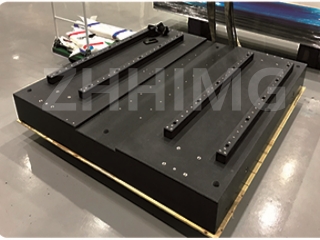

1. Use high-quality granite machine bases

To ensure the accuracy and stability of the inspection device, it is essential to use high-quality granite machine bases, which are manufactured to exacting standards. The granite used in the machine base should be of high quality and free from cracks or other defects that can affect its performance. The surface of the machine base should be flat and even, with no undulations or bumps that can cause instability during the inspection process.

2. Plan the machine base design

The design of the machine base should be carefully planned, taking into account the dimensions of the LCD panels that will be inspected, the type of inspection equipment, and the required clearance for operators to work. The machine base should be designed to provide maximum stability and minimize any vibration or movement during the inspection process. The base should be large enough to accommodate the LCD panels comfortably and allow for easy access to the inspection equipment.

3. Consider adding vibration damping elements

In some cases, the use of vibration damping elements, such as rubber or cork, may be necessary to further reduce any vibration or movement during the inspection process. These materials can be added to the machine base or between the inspection equipment and the base to help absorb any shock or vibration. The addition of such elements can help to improve the overall accuracy and reliability of the inspection device.

4. Regular maintenance

Regular maintenance of the machine base is essential to ensure that it remains in good condition and performs at optimum levels. The machine base should be cleaned regularly to remove any dirt or debris that can affect performance. Any cracks or other defects should be repaired promptly to ensure that the machine base remains stable and reliable.

In conclusion, the use of granite machine bases can significantly improve the performance and accuracy of LCD panel inspection devices. By choosing the highest quality granite and careful planning the machine base design, adding vibration damping elements where necessary and regular maintenance will lead to improved productivity while minimizing production errors.

Post time: Nov-01-2023