Granite is a unique material that has been used for precision processing devices for many years. It is known for its high stiffness and low thermal expansion, making it an ideal material for precision applications.

Here are some ways to use granite mechanical components for precision processing devices:

1. Granite surface plates

Granite surface plates are used in precision machining to ensure that the workpiece is held at the correct height and angle. They are used in machining processes such as grinding and milling to ensure that the workpiece is flat and parallel.

Granite surface plates can be cut and machined to precise dimensions, ensuring that they are flat and straight. They are also easy to clean and maintain, making them ideal for use in precision machining applications.

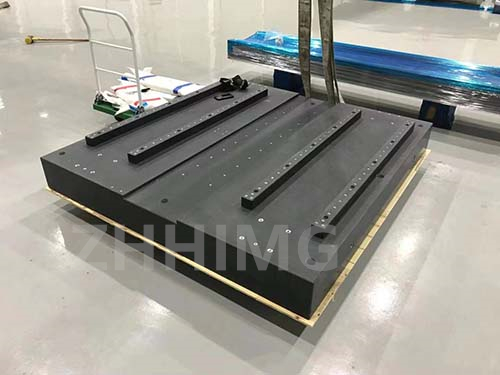

2. Granite machine bases

Granite machine bases are used in precision machinery to provide a stable and rigid base for the machine. The granite base helps to absorb vibrations and ensure that the machine operates smoothly.

Granite machine bases are also ideal for use in applications where temperature control is important. The low thermal expansion of granite means that it is less affected by temperature changes, ensuring that the machine maintains its accuracy over time.

3. Granite frames

Granite frames are used in precision measuring devices such as coordinate measuring machines (CMMs). The stiff and stable nature of granite makes it ideal for use in these applications, where accuracy and stability are paramount.

Granite frames are also resistant to wear and corrosion, ensuring that the machine maintains its accuracy over time.

4. Granite bearings

Granite bearings are used in precision machinery where low friction and high accuracy are required. These bearings are made from precision ground granite blocks and are used in applications where conventional bearings would not provide sufficient accuracy or stiffness.

Granite bearings are also ideal for use in applications where contamination is a concern, as they are less prone to wear and tear than traditional bearings.

In conclusion, granite mechanical components are a valuable asset in the precision processing device industry. They not only provide accuracy, but also stability, durability, and resistance to wear and corrosion. Their low thermal expansion and ability to absorb vibration make them a stand-out material compared to other materials. As technology evolves, the demand for precision machinery will only continue to grow, and the usage of granite mechanical components will be key in shaping the future of precision processing devices.

Post time: Nov-25-2023