Custom granite machine components have been increasing in popularity due to their various advantages in the manufacturing industry. Granite is a type of rock that is formed from volcanic activity and has unique properties that make it ideal for use in machine components.

Advantages of Custom Granite Machine Components

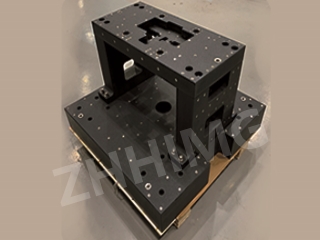

1. High Precision: Granite is extremely hard and dense, which makes it highly resistant to wear and tear. Custom granite machine components can be machined to very high tolerances, which results in highly accurate and precise machine components. This makes it ideal for tooling, gauging, and inspection equipment.

2. Stability: Granite has low thermal expansion characteristics, which makes it resistant to temperature changes. This means that custom granite machine components maintain their shape and size even when exposed to extreme temperature changes. This stability ensures that machines run smoothly and precisely, which is important in many manufacturing processes.

3. Durability: Granite is a very durable material that is resistant to chipping, cracking, and scratching. This makes it ideal for machine components that are subject to abrasive wear and tear. It can also withstand exposure to harsh chemicals, which is important in industrial manufacturing processes.

4. Aesthetic Appeal: Custom granite machine components have an aesthetic appeal that is unmatched by other materials. The natural colors and patterns of granite make it a visually appealing material that can enhance the look of machinery and equipment.

Disadvantages of Custom Granite Machine Components

1. Cost: Custom granite machine components can be more expensive than other materials due to the cost of the material and the specialized equipment needed to fabricate it. This cost can be prohibitive for some businesses, especially small businesses.

2. Weight: Granite is a heavy material, which can make it difficult to handle and transport. This added weight can also affect the performance of machinery and equipment, especially if the machinery is designed for use with lighter materials.

3. Limited Availability: Granite is a natural material that is not found in all parts of the world. This can make it difficult to source custom granite machine components, especially if the business is located in an area where granite is not readily available.

4. Limited Design Options: Granite is a natural material, and as such, it has limitations in terms of design options. This can limit the flexibility of custom granite machine components, especially if the design requires complex shapes or angles.

Conclusion

Custom granite machine components have many advantages in the manufacturing industry, including high precision, stability, durability, and aesthetic appeal. However, they also have some disadvantages, including cost, weight, limited availability, and limited design options. Despite these disadvantages, the benefits of custom granite machine components continue to make it an attractive material for many businesses looking to improve their manufacturing processes.

Post time: Oct-13-2023