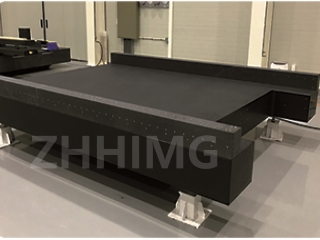

Granite air bearing stages are an essential part of precision equipment that is commonly used in the manufacturing and testing of semiconductors and microelectronics, optical devices, and satellites. These stages are composed of a granite base that houses a moving platform that is levitated by a thin layer of air and driven by electromagnetic motors and linear encoders. There are many unique qualities of granite air bearing stages that make them a preferred choice over many other types of stages.

Advantages of Granite Air Bearing Stages:

1. High Precision and Accuracy – Granite air bearing stages offer a high level of precision, it is capable of maintaining accuracy within a few nanometers. This is crucial in processes like lithography, where any error can cause significant changes in the final product.

2. High Load Capacity – Granite air bearing stages have a robust granite base that allows it to carry heavy loads, unlike other alternatives like ball bearing stages. This feature makes it ideal for handling large wafers and tools used in the production of semiconductors and microelectronics.

3. Frictionless Motion and Smoothness – Granite air bearing stages suspend the moving platform in a thin layer of air that eliminates any contact between the platform and the base. Thus, there is no friction between the moving parts, providing smooth and vibration-free motion.

4. High-Speed Capabilities – The electromagnetic motors used in granite air bearing stages allow for high-speed movement, making it ideal for positioning, scanning, and other high-precision tasks.

5. Longevity and Minimal Maintenance – The granite base that forms the foundation of the stage offers exceptional rigidity, thermal stability, and resistance to wear and tear. Hence, granite air bearing stages require minimal maintenance and offer a long lifespan.

Disadvantages of Granite Air Bearing Stages:

1. Cost – The advanced technology used in designing and manufacturing granite air bearing stages makes it a costly investment. This could be a drawback for smaller-scale businesses or companies with a tight budget.

2. Complex Installation – Granite air bearing stages require specialized knowledge and expertise during installation, calibration, and operation, making it challenging for non-experts.

3. Sensitivity to vibration – Even though granite air bearing stages are designed to provide smooth and vibration-free motion, they can be affected by external vibrations that disturb the floating platform's delicate balance.

In conclusion, granite air bearing stages are a highly effective and accurate solution for high-precision applications that require smooth and fast movement of large loads. Its robustness, durability, and long lifespan make it a preferred choice for many manufacturing, testing, and research operations. Although the high initial cost and complex installation might be a drawback, the advantages offered by granite air bearing stages outweigh their disadvantages, making them an excellent investment in precision equipment.

Post time: Oct-20-2023