Introduction

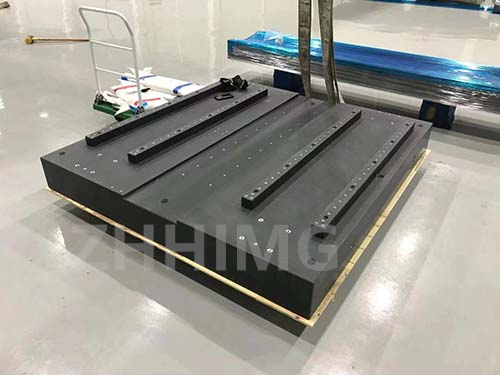

Granite research and design for the manufacturing process of liquid crystal display (LCD) panel devices has been a crucial subject of research. Granite has a natural resistance to vibrations, low thermal expansion coefficient, and high rigidity. The article highlights the advantages and disadvantages of granite components for LCD panel manufacturing processes.

Advantages

High Precision

Granite machine components are renowned for their high precision. The surface is subjected to rigorous checks to ensure it is flat and level. The process involves a computerized tool that complements the machinery to achieve reliable and error-free production. Moreover, granite is renowned for dimensional stability, which relies on its natural density and hardness. It helps to minimize thermal distortion and wear and tear of mechanical parts.

Low maintenance cost

Granite components are rigorous and come with high resistance to wear and tear. In turn, this translates to lower maintenance cost because of their durability and robustness. Besides, granite machine components require little maintenance because of their high thermal stability, which is pivotal for any LCD panel manufacturing process.

Thermal Stability

Granite components exhibit high thermal stability, which makes them suitable for hot weather. Due to their low expansion coefficients, granite components are less susceptible to thermally induced distortion. Components that warp or expand during the manufacturing process lead to variations in the thickness of the liquid crystal material (LCD). Granite components lead to consistency in manufacturing processes.

Disadvantages

Costly

Despite the impressive advantages of granite components, they come at a price. Granite is known for its high cost, which is mainly attributed to the labor-intensive mining process. Despite the initial high cost, granite components save maintenance and operating costs by providing a highly precise output and less maintenance cost.

Heavy in Weight

Granite components are heavy compared to most metals and plastics generally used for manufacturing purposes. Additionally, handling granite components can be challenging, especially when moving them from one point to another. As a result, a specialized team is usually required to move heavy granite machinery from one area to another.

Conclusion

Granite components for LCD panel manufacturing devices are an excellent choice due to their high precision, low maintenance cost, and thermal stability. Although they come at a high initial cost and are heavy, their durability, strength, and less maintenance cost make them an excellent option for manufacturing LCD panels. It is recommended that manufacturers embrace granite components in their LCD panel manufacturing processes due to the benefits they offer in terms of quality, efficiency, and cost-effectiveness.

Post time: Nov-29-2023