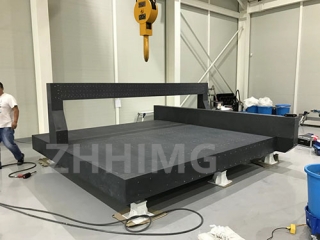

Granite is a natural stone that is widely used in various industries, including electronics. LCD panel inspection devices, used in the electronics industry, can be made up of granite components. Granite features several advantages and disadvantages when used in the production of such devices.

Advantages of Granite Components for LCD Panel Inspection Devices:

1. Durability and Longevity: Granite is one of the toughest materials and has excellent durability. It has a long lifespan and can withstand several years of use without wearing or breaking down.

2. Stability: Granite is highly stable, resistant to scratches and dents, and can maintain its shape even when subjected to various external pressures. This stability ensures the accuracy and precision of the inspection device.

3. High Temperature Tolerance: Granite Components are resistant to high temperatures, making it suitable for use in environments with high temperatures, such as those encountered during the production of LCD panels.

4. Low Thermal Expansion Coefficient: Granite has a low thermal expansion coefficient, making it highly resistant to thermal changes. This feature ensures that the inspection device’s parts remain stable, even when exposed to higher temperatures.

5. Non-Magnetic: Granite is non-magnetic, unlike most metals, which can be magnetized. This property ensures that the inspection device remains free of magnetic interference, ensuring accurate results.

6. Aesthetics: Granite offers an elegant and attractive finish, adding aesthetic value to the LCD panel inspection device. This feature is particularly important for products that customers and clients may see.

Disadvantages of Using Granite Components for LCD Panel Inspection Devices:

1. Weight: Granite is heavy, with a density close to 170 pounds per cubic foot. Use of granite components in the inspection device may make it bulky and hard to move.

2. Cost: Granite is relatively expensive compared to other materials like metals and plastics. This high cost may make it challenging to produce an affordable inspection device.

3. Brittle: Granite components are brittle and can be cracked or broken if subjected to heavy impacts or loads. Therefore, the inspection device must be handled with care.

4. Difficult to Process: Granite is challenging to work with, and it requires specialized tools and machinery to shape and polish it. This makes the production of the inspection device involving granite components somewhat technically demanding and labor-intensive.

In conclusion, the advantages of using granite components in LCD panel inspection devices outweigh the disadvantages. Granite offers excellent durability, stability, non-magnetic, high-temperature tolerance, low thermal expansion coefficient, and aesthetic value to the inspection device. The downsides of using granite components are primarily its weight, cost, brittleness, and technical difficulty in shaping it. Therefore, despite some limitations, the use of granite components is a wise choice for producing high-quality and durable LCD panel inspection devices.

Post time: Oct-27-2023