Industrial computed tomography (CT) has become an indispensable tool for quality inspection, reverse engineering, metrology, and scientific research in a wide range of industries. The accuracy, speed, and non-destructiveness of industrial CT depend on various factors, including the design and manufacturing of the machine base. Granite is one of the most popular materials for CT machine bases due to its unique properties, such as stability, stiffness, damping, thermal stability, and machinability. In this article, we will discuss the advantages and disadvantages of Granite machine bases for industrial CT.

Advantages of Granite Machine Base for Industrial CT

1. Stability: Granite has a low coefficient of thermal expansion, which means that its size and shape are relatively constant under different temperatures and humidity levels. This property ensures that the CT machine remains stable and accurate throughout its operation, without being affected by external factors such as vibrations, shocks, and deformations. Stable CT machines are essential for achieving high-quality and consistent results in various applications, such as defect detection, dimensional measurement, and material analysis.

2. Stiffness: Granite has a high Young's modulus, which means that it resists deformation under stress or load. This property ensures that the CT machine base maintains its shape and dimension, even under heavy loads or impacts. Stiff CT machines are essential for reducing errors and uncertainties in the CT images or data, especially for high-precision applications such as micro-CT and nano-CT.

3. Damping: Granite has a high damping coefficient, which means that it absorbs and dissipates energy or vibrations. This property ensures that the CT machine base reduces or eliminates the vibrations or noises generated by the CT system components, such as the X-ray tube, detectors, and stages. Damped CT machines are essential for improving the signal-to-noise ratio, minimizing the artifacts, and enhancing the spatial resolution of the CT images or data.

4. Thermal stability: Granite has a high thermal conductivity and a low thermal expansion coefficient, which means that it can dissipate or absorb heat efficiently without changing its size or shape significantly. This property ensures that the CT machine base remains stable and accurate even under thermal cycling or gradient conditions, such as during extended scanning sessions or when using high-energy X-rays.

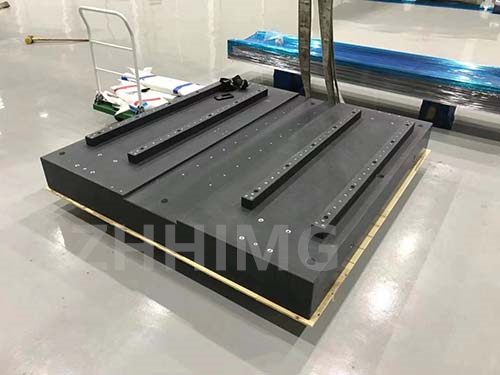

5. Machinability: Granite can be machined or polished to high accuracy and smoothness levels, which means that the CT machine base can be fabricated with precise shapes, sizes, and surface finishes. This property ensures that the CT machine base fits seamlessly with other CT system components, such as the gantry, the enclosure, and the shielding. Machinable CT machine bases are essential for reducing assembly errors, enhancing safety, and improving the overall performance of the CT system.

Disadvantages of Granite Machine Base for Industrial CT

1. Weight: Granite is a dense and heavy material, which means that the CT machine base made of granite can be challenging to transport, install, or relocate. This property may require special handling equipment, such as cranes or hoists, to move the CT machine base, which can increase the cost and time of the CT system installation or maintenance. However, this disadvantage can be mitigated by designing the CT machine base with modular or detachable components, and by optimizing the layout or the accessibility of the CT system.

2. Cost: Granite is a valuable and premium material, which means that the CT machine base made of granite can be more expensive than other materials, such as steel or aluminum. This property may increase the initial cost of the CT system, especially for small and medium-sized businesses or research laboratories with limited budgets. However, this disadvantage can be offset by the long-term benefits of the granite machine base, such as the improved accuracy, stability, and durability, and the reduced maintenance, downtime, and replacement costs.

Conclusion

Granite machine bases offer several advantages and a few disadvantages for industrial CT applications. The stability, stiffness, damping, thermal stability, and machinability of granite make it an ideal material for high-precision and high-throughput CT systems that require exceptional accuracy, reliability, and flexibility. The weight and cost of a granite machine base may pose some challenges, but they can be overcome by careful design, planning, and optimization of the CT system. In summary, granite machine bases are a valuable and worthwhile investment for industrial CT applications that demand high-quality results and long-term benefits.

Post time: Dec-19-2023