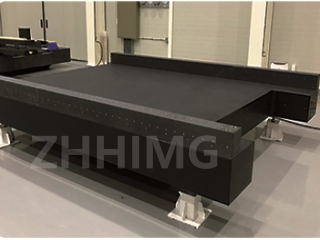

Granite is a type of igneous rock that is known for its durability, hardness, and stability. These qualities make granite an ideal material for machine bases and for use in wafer processing. In this article, we will discuss the advantages and disadvantages of using granite machine bases in wafer processing.

Advantages of Granite Machine Base:

1. Stability: Granite has a low coefficient of thermal expansion, which means it remains stable even when exposed to high temperatures. This stability ensures that the machine base remains in place and doesn't move during wafer processing.

2. Durability: Granite is one of the hardest materials, making it highly resistant to wear and tear. This durability ensures that the machine base can withstand the pressure and vibrations produced during wafer processing.

3. Low Vibration: Due to the inherent stability and hardness of granite, it produces minimal vibration during wafer processing. This low vibration minimizes the risk of damage to the wafer and ensures precision and accuracy in the processing.

4. Accuracy: The high level of stability and low vibration of the granite machine base ensures accuracy in wafer processing. This accuracy is essential for creating high-quality semiconductors, which require precision in their manufacturing process.

5. Ease of Maintenance: Granite is a non-porous material, making it easy to clean and maintain. This reduces the time and labor required for maintenance and increases the overall efficiency of the wafer processing operation.

Disadvantages of Granite Machine Base:

1. Cost: One of the main disadvantages of granite machine bases is their relatively high cost compared to other materials. This is due to the difficulty and expense of quarrying, transporting, and shaping the granite.

2. Weight: Granite is a dense material, making it heavy and difficult to move. This can make it challenging to reposition the machine base during installation or maintenance.

3. Machining Difficulty: Granite is a hard and abrasive material, which makes it difficult to machine and shape. This can increase the time and cost required to fabricate the machine base.

Conclusion:

The use of granite machine bases in wafer processing offers many advantages, including stability, durability, low vibration, accuracy, and ease of maintenance. However, these benefits come at a higher cost and require specialized equipment and expertise to manufacture and machine the granite machine base. Despite these disadvantages, the advantages of granite machine bases make them a popular choice for wafer processing operations where precision and accuracy are critical.

Post time: Nov-07-2023