The advantages and disadvantages of granite table for precision assembly device

Introduction:

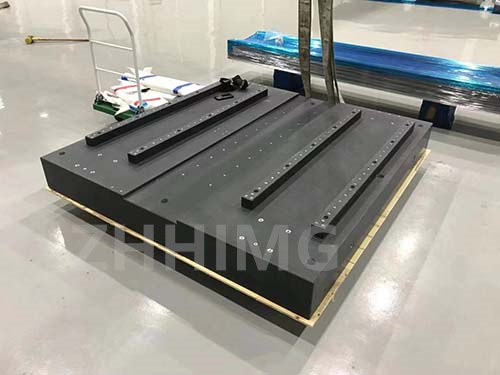

Granite is a hard and durable natural stone that is widely used for various purposes. One of its most common applications is for precision assembly devices such as granite tables. Granite tables are used in industries like manufacturing, engineering, and research to provide a flat, stable, and reliable surface for the assembly of precision parts. This article aims to discuss the advantages and disadvantages of using granite table for precision assembly devices.

Advantages:

1. Stability: One of the key advantages of using granite tables is their exceptional stability. Granite is a hard and dense material that does not easily warp, bend, or deform, even under heavy loads. This property makes it ideal for precision applications where a stable surface is essential for accurate assembly.

2. Flatness: Another key advantage of granite tables is their flatness. Granite is an inherently stable material with a uniform grain structure that allows for extremely flat surfaces. This means that when precision parts are placed on a granite table, they have a stable and flat surface to rest on, which is crucial for accurate assembly.

3. Durability: Granite tables are highly durable and can withstand heavy usage without deteriorating. Unlike wood or plastic tables, granite tables can resist scratches, dents, and chips, making them an ideal choice for high-traffic areas.

4. Corrosion-resistant: Granite is resistant to most chemicals, including acids and alkalis, making it ideal for use in harsh environments. This property ensures that the table remains intact even when exposed to corrosive substances.

5. Aesthetics: Granite tables offer an attractive and professional appearance, which gives them an edge over other types of tables. They can blend seamlessly with other equipment in the assembly line, enhancing the overall aesthetics of the workspace.

Disadvantages:

1. Weight: Granite tables are extremely heavy, which makes them difficult to move around. They require specialized equipment and are not portable, which may limit their usability in certain applications.

2. Cost: Granite tables are more expensive compared to other tables made from materials like wood or plastic. As a result, they may not be suitable for small scale businesses, or businesses that are working within tight budgets.

3. Maintenance: Granite tables require regular cleaning and maintenance to maintain their luster and flatness. This can be an added expense for businesses that lack the resources to afford a support team or a maintenance department.

4. Fragility: Although granite is a durable material, it is prone to cracking and chipping if exposed to excessive force or impact. This means that the table may require frequent inspection to ensure that it is still in good condition.

Conclusion:

In conclusion, the advantages of using granite tables for precision assembly devices far outweigh the disadvantages. Granite tables provide a stable and flat surface that is essential for accurate assembly, which makes them ideal for businesses that are committed to quality assurance. Although they may be heavy, expensive, and require maintenance, they provide long-term value in terms of durability and resistance to corrosion and harsh environments.

If you want to know more information about granite surface plate with high precision or need any further assistance, contact us freely: info@zhhimg.com

Post time: Nov-16-2023