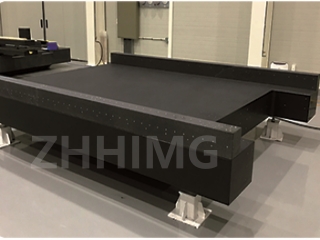

Granite is a popular material for constructing inspection devices used in the LCD panel industry. It is a naturally occurring stone that is known for its high durability, resistance to wear and tear, and stability. The use of granite as a base for LCD panel inspection devices is not without certain advantages and disadvantages. In this essay, we will explore the advantages and disadvantages of using granite as a base material for LCD panel inspection devices.

Advantages of Granite Base for LCD Panel Inspection Devices

1. High Durability: The primary advantage of using granite as a base for LCD panel inspection devices is its high durability. It can withstand the wear and tear of heavy usage and can last for years without showing signs of wear and tear. This is an important consideration, especially in a manufacturing setting where high precision and accuracy are critical.

2. Stability: Granite is a naturally stable material with a low coefficient of thermal expansion, which means it is unlikely to expand or contract due to heat or cold. This makes it an ideal material for the base of an inspection device that requires high precision and accuracy.

3. Vibration Dampening: Granite has a high density, which makes it an excellent material for dampening vibrations. This is important in the LCD panel industry, where even the slightest vibrations can affect the quality of the product.

4. Easy to Clean: Granite is naturally impervious to water and stains, making it easy to clean and maintain. This is important in an industry where cleanliness and hygiene are critical.

5. Aesthetically Pleasing: Granite is a natural stone that is aesthetically pleasing. It adds a touch of elegance to any LCD panel inspection device, making it more appealing to use.

Disadvantages of Granite Base for LCD Panel Inspection Devices

1. Heavy: Granite is a heavy material, which makes it difficult to move or transport. This can be a disadvantage, especially in a manufacturing setting where the inspection device needs to be moved frequently.

2. Cost: Granite is a natural stone that is expensive to extract and process, making it a costly choice for a base material. This can make it difficult for small businesses or startups to afford.

3. Limited Design Options: Granite is a natural stone with limited design options. This means that the base of the inspection device can appear monotonous or dull, especially when compared to other modern materials with a wider range of design options.

4. Temperature Sensitivity: Although granite is known for its stability, it can still be affected by extreme temperatures. It can expand or contract, affecting its accuracy in measuring LCD panels.

5. Limited Availability: Granite is a scarce natural resource that is only found in certain parts of the world. This means that it may not be available in all parts of the world, making it difficult for some businesses to access.

Conclusion

Granite is an excellent material for constructing LCD panel inspection devices, especially in terms of durability, stability, vibration dampening, and ease of cleaning. However, its heaviness, high cost, limited design options, sensitivity to extreme temperatures, and limited availability can be potential downsides. Despite its disadvantages, the advantages of using granite as a base material for LCD panel inspection devices far outweigh the negatives. Granite is a reliable and long-lasting material that can help ensure high precision, accuracy, and quality in the LCD panel industry.

Post time: Nov-01-2023