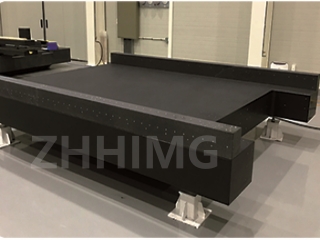

Precision granite is a type of granite that has been finely polished and calibrated to very precise standards. It is a popular material for a wide range of applications, including LCD panel inspection devices. There are many advantages to using precision granite in these types of devices, but there are also some potential drawbacks that should be considered.

One of the biggest advantages of precision granite is its accuracy and stability. Because it is made from a very dense and uniform material, it is able to maintain its shape and dimensions very precisely over time. This means that it can provide a stable and accurate reference surface for measuring and inspecting LCD panels. Additionally, it resists deformation and wear from repeated use, which ensures that it retains its accuracy even after many years of service.

Another advantage of precision granite is its durability and resistance to damage. It is a very hard and tough material, meaning that it can withstand a lot of wear and tear without becoming damaged. This makes it ideal for use in environments where LCD panels may be moved around or subjected to various forms of stress or impact. Additionally, it is highly resistant to thermal changes, which means that it can maintain its dimensional stability even in environments that experience large temperature swings.

Another advantage of precision granite is its aesthetic appeal. It has a beautiful natural appearance that can add a touch of elegance and sophistication to any LCD panel inspection device. This can be especially important for companies that value the appearance of their equipment and want to project a professional image to their clients.

However, there are also some potential disadvantages of using precision granite in LCD panel inspection devices. One of the main disadvantages is the cost. Precision granite is a premium material that can be expensive to purchase and work with. This may make it prohibitively costly for some companies, especially smaller ones that may not have the resources to invest in high-end equipment.

Another potential drawback of precision granite is its weight. It is a very dense and heavy material, which means that it can be difficult to move around and position within an LCD panel inspection device. This can make it challenging for technicians to use the equipment effectively and may require additional support structures or specialized tools to handle and position the granite accurately.

Finally, precision granite may not be compatible with all types of LCD panel inspection devices. Some devices may require specialized materials or approaches to achieve the necessary accuracy and stability, which may make precision granite less suitable for certain applications.

In conclusion, precision granite is a highly effective material for use in LCD panel inspection devices. It offers a range of benefits, including accuracy, stability, durability, and aesthetic appeal. However, there are also some potential drawbacks to consider, including cost, weight, and compatibility. Ultimately, the decision to use precision granite will depend on the specific needs and requirements of each individual application.

Post time: Oct-23-2023