Optical waveguide positioning devices are used to accurately position optical waveguides in a variety of applications, from telecommunications to medical devices. When it comes to the production of these devices, the choice of assembly method can greatly impact their quality, durability, and performance.

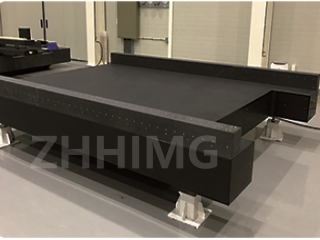

One of the most advantageous methods of assembly for optical waveguide positioning devices is granite assembly. Granite is a hard and non-porous material that offers a number of benefits over other materials such as aluminum or plastic.

Firstly, granite is extremely stable and has a low coefficient of thermal expansion. This means that it won't expand or contract significantly with temperature changes, ensuring that the devices remain stable and reliable even in harsh environments. This stability is particularly important in precision applications, such as telecommunications, where the positioning of the waveguides must be accurate and consistent.

Secondly, granite is extremely hard and durable. It is not easily scratched or damaged, making it ideal for use in production environments where devices may be subject to wear and tear. Granite is also resistant to chemical corrosion, which is important in applications where the devices may come into contact with chemicals that could damage other materials.

Furthermore, granite's high density makes it an excellent material for vibration dampening. This is critical in optical waveguide positioning devices where even small vibrations can disrupt the performance of the system. The use of granite can help to absorb these vibrations, ensuring that the devices remain stable and reliable.

In addition to its material properties, granite assembly also offers a number of practical advantages. For example, granite can be machined to very tight tolerances, ensuring that the devices are accurately manufactured to precise specifications. Granite is also easy to clean and maintain, ensuring that the devices remain hygienic and free from contaminants.

Finally, granite is relatively easy to work with and can be processed using a variety of techniques, including CNC machining, grinding, and polishing. This versatility makes it a popular choice for a range of applications, not just optical waveguide positioning devices.

In conclusion, the advantages of granite assembly for optical waveguide positioning devices are clear. Granite's stability, durability, resistance to corrosion and vibration dampening properties make it an ideal choice for precision applications where accuracy and reliability are critical. Furthermore, the ease of machining and maintenance makes it a practical and cost-effective choice for manufacturers.

Post time: Dec-04-2023