Granite is a naturally strong and durable material that has been used for centuries in construction and machinery. As a result, it has become a popular choice to manufacture machine components such as bases, columns, and supports. In this article, we will explore the many advantages of granite machine components.

Strength and Durability

One of the most significant advantages of granite machine components is their strength and durability. Granite is a dense, hard rock that can withstand immense pressure and weight, making it an excellent choice for machine components that need to support heavy loads. Granite is also resistant to corrosion, acid, and chemicals, which means it can withstand harsh conditions without deteriorating.

Dimensional Stability

Granite is known for its dimensional stability, meaning it maintains its shape and size, even when exposed to temperature changes and other environmental factors. This is a crucial advantage in machine components, as any deviation in size or shape can lead to inaccuracies in the machinery's performance. Because granite is so stable, it can ensure that machine components continue to function correctly and maintain their accuracy over time.

Reduced Vibration

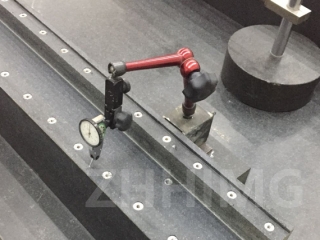

Another advantage of granite machine components is their ability to absorb vibration. When machines are in operation, there is typically a lot of vibration generated, which can cause damage to the machinery and surrounding structures. However, granite machine components can absorb the vibration, reducing the impact it has on the machinery while improving the overall performance and accuracy of the machine.

Improved Accuracy

Granite is a material that can be worked to an incredibly high degree of accuracy, which is why it is often used for precision machine components. Granite machine components can be machined to exact tolerances, resulting in machinery that performs consistently and with high precision. This is a significant advantage for industries such as aerospace, defense, and medical equipment, where precision is of the utmost importance.

Reduced Maintenance

Finally, granite machine components require little to no maintenance, making them a cost-effective choice for machinery manufacturers. Because granite is so durable, it is unlikely to wear or deteriorate over time, which means less maintenance and repair work is required. This can save time and money in the long run, making granite machine components an attractive option for many machinery manufacturers.

Conclusion

In conclusion, granite machine components offer many advantages that make them an attractive choice for machinery manufacturers. Granite's strength, durability, dimensional stability, ability to absorb vibration, high accuracy, and low maintenance requirements all contribute to making it an excellent material for precision machinery components. It is no wonder that granite continues to be a popular choice for machine components worldwide.

Post time: Oct-10-2023