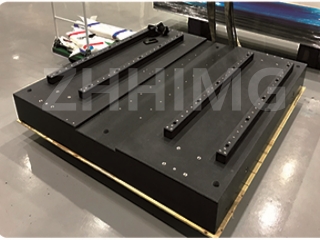

Custom granite machine components have a wide range of application areas due to the various properties and characteristics that they possess. These granite machine components are made from high-quality granite material, which is known for its durability, hardness, and resistance to wear and tear. Therefore, they are widely used in various industries that require high precision and accuracy in their operations. In this article, we will look at some of the application areas of custom granite machine components.

1. Precision Engineering Industry

Custom granite machine components are widely used in the precision engineering industry, which includes medical, automotive, aerospace, and electronics industries. They are used as base plates, worktables, and measuring components in high-precision machine tools. Granite offers high stability, which is essential in the precision industry to achieve the desired accuracy, and it is also resistant to environmental factors such as temperature changes and vibrations.

2. Metrology Industry

Custom granite machine components are also used in the metrology industry, which involves measurement and calibration of dimensional and geometrical features. Granite machine components are used as measuring bases, surface plates, and machine tool calibration standards. The high stability and flatness qualities of granite help to achieve high measurement accuracy, which is essential in the metrology industry.

3. Packaging Industry

The packaging industry involves the production of various packaging materials such as cartons, bottles, and containers. Custom granite machine components are used in packaging machines such as filling machines, sealing machines, and labeling machines. The granite components offer high stability and wear resistance, which helps to improve the efficiency of the packaging process and reduce downtime.

4. Glass Industry

The glass industry involves the production of various glass products such as sheets, bottles, and containers. Custom granite machine components are used in glass manufacturing equipment, such as glass cutting and polishing machines. The high hardness and wear resistance of granite help to improve the accuracy and efficiency of the glass manufacturing process.

5. Semiconductor Industry

The semiconductor industry involves the production of electronic components such as microchips and integrated circuits. Custom granite machine components are used in semiconductor manufacturing equipment, such as wafer inspection machines and lithography machines. The high stability and flatness of granite help to achieve high accuracy and precision in the manufacturing process.

6. Food Industry

The food industry involves the production of various food products such as snacks, beverages, and dairy products. Custom granite machine components are used in food processing equipment, such as cutting and grinding machines. The high hardness and wear resistance of granite help to improve the efficiency and hygiene of the food processing process.

In conclusion, custom granite machine components have a wide range of application areas, including precision engineering, metrology, packaging, glass, semiconductor, and food industries. These components offer high stability, accuracy, and wear resistance, which are essential in various industries that require high precision and accuracy in their operations. Investing in custom granite machine components can help businesses improve their efficiency, reduce downtime, and increase profitability.

Post time: Oct-13-2023