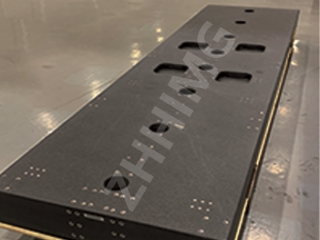

Granite is a natural stone formed through the cooling and solidification of volcanic magma or lava. It is a very dense and durable material that is highly resistant to scratching, staining, and heat. Granite is used extensively in the construction industry for building materials such as countertops, flooring, and facades because of its strength and durability. In addition to these applications, granite has also found its way into the precision assembly device industry, where it is widely used as a base material.

Precision assembly devices are used in a variety of industries such as automotive, aerospace, and medical, where exacting standards of accuracy and reliability are essential. A base material is required for these devices that can provide excellent vibration damping, high stiffness, and thermal stability. Granite meets all of these requirements, making it the ideal choice for the base of precision assembly devices.

One of the primary applications of granite in precision assembly devices is in the production of coordinate measuring machines (CMMs). CMMs are used in manufacturing plants to measure the dimensions of components to a high degree of accuracy. These machines use a granite base because it provides a stable and reliable platform for the measurement system. Granite has an extremely low coefficient of thermal expansion, which means that it is highly resistant to changes in temperature. This makes it an ideal material for maintaining the accuracy of the measuring system.

Granite is also widely used in the production of optical alignment systems. These systems are used to align optical components to an extremely high degree of accuracy. A granite base material is essential for these systems because it provides a high degree of stiffness, which is required to maintain the alignment of the optical components. Granite is also highly resistant to vibration, which makes it ideal for use in environments where vibration levels are high, such as manufacturing plants.

Another application of granite in precision assembly devices is in the production of semiconductor manufacturing equipment. Semiconductor manufacturing requires a high degree of precision to ensure that components are manufactured to exacting standards. A granite base provides the required stability and stiffness needed for the manufacturing equipment, which helps to ensure that the components are manufactured to the required specifications.

In addition to these applications, granite is also used in the production of laboratory equipment, such as weighing balances and spectroscopy equipment. These devices require a high degree of stability to ensure accurate measurements. A granite base provides the required stability and stiffness needed for these types of devices, making it an ideal choice.

In conclusion, granite is a highly versatile material that has found widespread use in the precision engineering industry. Its properties of high stiffness, vibration damping, and thermal stability make it the ideal choice for the base material of precision assembly devices. From CMMs to semiconductor manufacturing equipment, granite has found its way into a wide range of applications, helping to ensure that the devices manufactured to exacting standards of accuracy and reliability. As the demand for ever more precise components continues to increase, it is likely that the use of granite in precision engineering will continue to grow.

Post time: Nov-21-2023