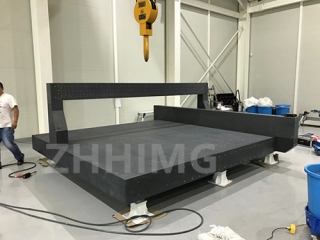

Precision granite assembly refers to a manufacturing process that involves the use of meticulously cut and calibrated granite components that are used in the assembly of various devices. The precision granite assembly has various applications, including the development of LCD panel inspection device products.

LCD Panel Inspection Device Products:

LCD panel inspection device products are electronic devices used in the quality control of liquid crystal display (LCD) panels. They help to detect various defects such as burn-in and dead pixels, ensure accurate color reproduction, and optimal brightness. Precision granite assembly has revolutionized the development of such devices, significantly improving their functionality, and the quality of LCD panels they inspect.

Applications of Precision Granite Assembly in the Development of LCD Panel Inspection Devices:

1. Precision Leveling:

Granite components are used to create a flat surface on which LCD panels are placed during inspection, ensuring precise and accurate leveling. The granite components used for this are perfectly engineered to achieve high accuracy and stability, which guarantees the high precision of the inspection.

2. Stability and Durability:

Granite components are among the most stable and durable materials used in the precision factor of an LCD panel inspection device. They provide an anti-vibration platform for the inspection equipment, which guarantees accuracy and enhances performance. The stability of Granite components greatly reduces equipment maintenance costs and allows for manufacturing precision devices that can withstand harsh conditions and environments.

3. Thermal Stability:

One of the unique characteristics of granite components is that they have exceptional thermal stability. This characteristic makes them ideal for use in manufacturing LCD panel inspection devices as they perform well even when subjected to ambient temperature variations. The thermal stability provided by precision granite assembly components ensures that LCD panels are inspected under optimal temperature conditions, thus achieving maximum precision and manufacturing the best, high-quality products.

4. High-Quality Calibration Standards:

Precision granite assembly components are used to develop calibration standards used in the manufacturing of LCD panel inspection device products. The high-quality calibration standards guarantee that the devices meet the highest precision, accuracy, and stability standards required in meeting the market demands for high-quality LCD panels.

5. Reduced Error:

Errors in LCD panel inspection devices have significant consequences as they may lead to the production of hundreds of defective LCD panels. Precision granite assembly components are carefully manufactured to reduce the level of error during device calibration, thus improving the precision and accuracy of inspection.

6. Enhanced Productivity:

Precision granite assembly components improve the productivity of LCD panel inspection devices. They allow for the manufacturing of robust, stable, and reliable devices that conduct faster and more accurate inspections. The high performance of Precision granite assembly components guarantees optimal LCD panel quality, which minimizes production time and materials wastage.

Conclusion:

In summary, precision granite assembly plays a vital role in the development of high-quality LCD panel inspection device products. It provides the necessary precision and accuracy needed to produce high-quality LCD panels, thus improving the overall quality of life. The applications of precision granite assembly in the manufacturing of LCD panel inspection devices provide new possibilities for the future of this technology, which continues to benefit the electronic manufacturing industry at large.

Post time: Nov-06-2023