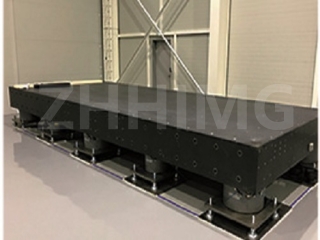

Optical waveguide positioning devices are an essential part of optical communication systems. These devices are used to accurately position waveguides on the substrate to ensure they can transmit signals accurately and efficiently. One of the most commonly used substrates for these devices is granite. However, while granite offers several advantages, there are also some defects that can affect the assembly process.

Granite is a natural stone that is hard and durable, which makes it ideal for use as a substrate in optical waveguide positioning devices. It has excellent thermal stability and is resistant to environmental effects, which ensures that it can maintain its shape and structure over time. Granite also has a low coefficient of thermal expansion, which means it does not deform significantly when exposed to temperature changes. This characteristic is essential because it ensures that the waveguides do not move or shift due to thermal expansion.

One of the significant defects of granite is its surface roughness. Granite has a porous and uneven surface that can cause problems during the assembly process. Since waveguides require a smooth and flat surface to ensure they can transmit signals accurately, the rough surface of granite can lead to signal loss and interference. Moreover, the rough surface can make it difficult to align and position the waveguides accurately.

Another defect of granite is its brittleness. Granite is a hard and robust material, but it is also brittle. The brittleness makes it susceptible to cracking, chipping, and breaking when exposed to stress and pressure. During the assembly process, the pressure and stress exerted on the granite substrate, such as from the mounting process, can cause cracks or chips that can affect the performance of the waveguides. The brittleness of the granite substrate also means that it requires careful handling to avoid damage during transportation and installation.

Granite is also vulnerable to moisture and humidity, which can cause it to expand and contract. When exposed to moisture, granite can absorb water, which can cause it to swell and create stress within the material. This stress can lead to significant cracking or even the complete failure of the substrate. Moisture also affects the adhesives used in the assembly process, which can result in weak bonds, leading to issues like signal loss.

To conclude, while granite is a popular substrate for optical waveguide positioning devices, it still has some defects that can affect the assembly process. Granite's rough surface can lead to signal loss, while its brittleness makes it vulnerable to cracking and chipping under pressure. Lastly, moisture and humidity can cause significant damage to the substrate. However, with careful handling and attention to detail, these defects can be managed effectively to ensure optimal performance of the waveguide positioning device.

Post time: Dec-04-2023