Wafer processing equipment is an essential tool in the manufacturing process of electronic components. The equipment utilizes granite components to ensure stability and accuracy during the manufacturing process. Granite is a naturally occurring rock with excellent thermal stability and low thermal expansion properties, making it an ideal material for use in wafer processing equipment. In this article, we will look at the requirements of wafer processing equipment granite components on the working environment and how to maintain the working environment.

Requirements of Wafer Processing Equipment Granite Components on the Working Environment

1. Temperature Control

Granite components used in wafer processing equipment require a stable working environment to maintain their accuracy. The working environment must be maintained within a particular temperature range to ensure that the granite components do not expand or contract. Temperature fluctuations can cause the granite components to expand or contract, which can result in inaccuracies during the manufacturing process.

2. Cleanliness

Wafer processing equipment granite components require a clean working environment. The air in the working environment should be free from particles that can contaminate the equipment. Particles in the air can settle on the granite components and interfere with the manufacturing process. The working environment should also be free from dust, debris, and other contaminants that can affect the accuracy of the equipment.

3. Humidity Control

High humidity levels can cause problems with wafer processing equipment granite components. Granite is porous and can absorb moisture from the surrounding environment. High humidity levels can cause the granite components to swell, which can affect the accuracy of the equipment. The working environment should be maintained at a humidity level between 40-60% to prevent this problem.

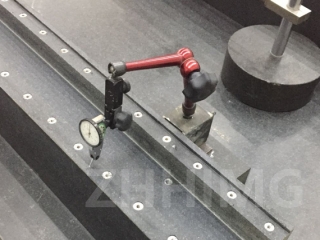

4. Vibration Control

Granite components used in wafer processing equipment are highly sensitive to vibrations. Vibrations can cause the granite components to move, which can result in inaccuracies during the manufacturing process. The working environment should be free from vibration sources such as heavy machinery and traffic to prevent this problem.

How to Maintain the Working Environment

1. Temperature Control

Maintaining a stable temperature in the working environment is critical for wafer processing equipment. The temperature should be maintained within a range specified by the manufacturer. This can be achieved by installing air conditioning units, insulation, and temperature monitoring systems to ensure that the equipment operates in a stable environment.

2. Cleanliness

Maintaining a clean working environment is essential for the proper functioning of the wafer processing equipment. The air filters should be changed regularly, and air ducts should be cleaned regularly to prevent the accumulation of dust and particles. The floors and surfaces should be cleaned daily to prevent debris accumulation.

3. Humidity Control

Maintaining a stable humidity level is essential for the proper functioning of the wafer processing equipment. A dehumidifier can be used to maintain the required humidity level. Humidity sensors can also be installed to monitor the humidity level in the working environment.

4. Vibration Control

To prevent vibrations from affecting the wafer processing equipment, the working environment must be free from vibration sources. Heavy machinery and traffic should be located away from the manufacturing area. Vibration dampening systems can also be installed to absorb any vibrations that may occur.

In conclusion, wafer processing equipment granite components require a stable and controlled working environment to ensure accuracy and reliability during the manufacturing process. Temperature control, cleanliness, humidity control, and vibration control are essential to maintain the equipment's proper functioning. Regular maintenance and monitoring of the working environment are crucial to prevent any problems that may affect the equipment's performance. By following these guidelines, manufacturers can maximize the performance of their wafer processing equipment and produce high-quality electronic components.

Post time: Jan-02-2024