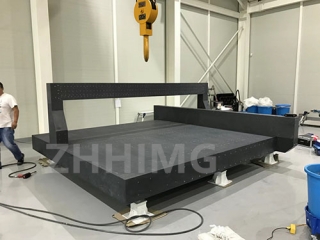

A precision granite pedestal base is a tool used in the manufacturing industry as a stable and flat surface for the measurement of precision equipment such as CMMs, optical comparators, and other measuring tools. This type of base is constructed from a single block of granite, which is selected for its high stability, low thermal expansion coefficient, and flatness.

The process of manufacturing a precision granite pedestal base involves careful selection and preparation of the granite block. The block is first inspected for flaws such as cracks, fissures, and defects. Once the block is deemed suitable for use, it is then cut into the desired shape and size using precision machinery.

In addition to cutting, the base will undergo a lengthy process of smoothing, flattening, and polishing. These stages are crucial to ensure the final product delivers optimal precision, accuracy, and stability. Granite is an excellent material for use in pedestal bases because of its natural stability and ability to resist temperature changes. This ensures that the base maintains its precision measurement capabilities even under varying environmental conditions.

One of the significant advantages of using a precision granite pedestal base is its accuracy in measurements. This is particularly important in the manufacturing industry where precision is essential in achieving high-quality products. The flat, level surface of the granite base provides an ideal foundation for measuring tools, ensuring that measurements can be taken with high accuracy.

Another advantage of the precision granite pedestal base is its long-lasting durability. Granite is a hard, strong material that can withstand heavy loads without cracking or chipping. This ensures that the pedestal base can be used for extended periods without losing its key characteristics of flatness, stability, and accuracy.

In conclusion, a precision granite pedestal base is an essential tool in the manufacturing industry for achieving high-quality precision in products. Its unique properties of stability, accuracy, and durability make it an indispensable tool used by professionals in various industries worldwide. By using this tool, manufacturers can ensure that their products meet the high standards of quality demanded by consumers.

Post time: Jan-23-2024