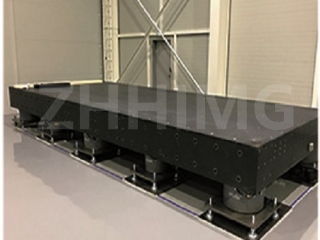

When it comes to choosing a base for laser processing products, the material that the base is made of can significantly affect the performance and quality of the processing. There are different materials to choose from, but granite has proven to be an excellent choice for a base due to its unique properties and advantages over metal.

One of the primary reasons why granite is a preferred material for laser processing product bases is its exceptional stability. Granite is known for its ability to maintain its stable form, even under extreme conditions, which is crucial for laser processing machines that require consistently precise movements. The stability of granite helps reduce vibration, which can affect the accuracy and quality of the laser processing.

Granite is also an excellent material for absorbing vibrations and reducing sound transmission. As the laser processing machines operate, they generate vibrations and noise that can affect other equipment in the surrounding environment. The use of granite bases greatly minimizes these issues, creating a more stable and peaceful working environment.

Another valuable property of granite that makes it an ideal choice for laser processing bases is its resistance to thermal change. Laser processing machines generate high amounts of heat during use, but because granite is an insulator, it helps dissipate heat effectively, keeping the machines cool and maintaining consistent performance levels.

In terms of maintenance, granite is also a low-maintenance material that requires minimal effort, especially when compared to metal. Granite is resistant to corrosion, rust, and chemical damage, which means that it is less likely to deteriorate over time, and there is less need for constant upkeep, saving costs and minimizing downtime.

It is important to note that the choice of the base material for laser processing products is significant to achieve maximum performance and efficiency. While metal is a popular material option for bases, the unique properties of granite make it an excellent choice that can enhance the overall quality and accuracy of laser processing.

In conclusion, choosing granite as a base for laser processing products offer several advantages over metal. Granite's exceptional stability, low maintenance, resistance to thermal change, and ability to absorb vibrations make it an ideal material for laser processing bases. Investing in granite bases can enhance the overall efficiency and precision of processes while also creating a more stable and conducive working environment.

Post time: Nov-10-2023