Granite is a popular material choice for components used in devices for LCD panel manufacturing processes. While metal is also a common choice for such components, granite has several advantages that make it a superior option. In this article, we will explore why granite should be the preferred choice over metal for these components.

First and foremost, granite is an extremely stable material. It does not warp or bend over time, which makes it an ideal material for precision engineering and manufacturing. When it comes to manufacturing LCD panels, precision is important, and any deviations can have a significant impact on the quality of the final product. Granite's stability helps ensure that the components used in this process are consistently accurate.

Another advantage of granite is its resistance to temperature changes. In the LCD panel manufacturing process, the machines and equipment used generate a lot of heat. This can cause metal components to expand and contract, which can affect their accuracy and performance. Granite, on the other hand, is not affected by temperature changes, making it a more reliable material choice for these components.

Granite is also extremely hard and durable. This means that it can withstand wear and tear over time, and it is less likely to become damaged or deformed due to repeated use. The durability of granite makes it a cost-effective choice for component manufacturing in the long run, as it does not need to be replaced as frequently as other materials.

Another benefit of granite is that it is resistant to corrosion. This is particularly important when it comes to the manufacturing of LCD panels, as the components used in this process may come into contact with chemicals or other substances that can cause corrosion. With granite components, manufacturers can ensure that their equipment and products remain in good condition over time.

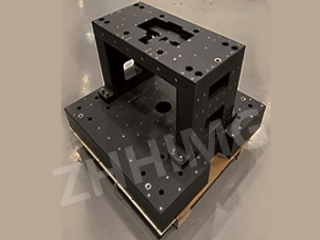

Finally, granite is a visually appealing material that adds a touch of elegance to any product it is used in. This is not a critical factor when it comes to manufacturing LCD panels, but it can be a nice added bonus. Granite components look sleek and professional, which can help boost the overall look and feel of the final product.

In conclusion, there are several reasons why granite is a better material choice over metal for components used in devices for LCD panel manufacturing processes. Its stability, resistance to temperature changes, durability, resistance to corrosion, and visual appeal all make it an ideal material for this application. By using granite components, manufacturers can ensure that their equipment and products are of the highest quality and that they stand the test of time.

Post time: Nov-29-2023