When it comes to LCD panel inspection devices, the components that make up the device play a critical role in the overall performance and functionality. One of the key components that can dramatically impact the performance of the device is the material used to construct the components. Two common materials used for the components of LCD panel inspection devices are granite and metal. However, in this article, we will discuss why granite is a better option than metal for these components.

Durability

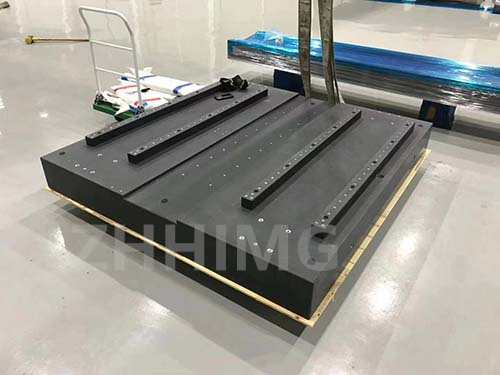

One of the most significant advantages of using granite for components is its durability. Granite is a naturally occurring rock that is incredibly dense and strong. It is highly resistant to scratches, chipping, and cracking. This property makes it an optimal choice for constructing components in an LCD panel inspection device because such a device is subject to frequent and intense movements.

Granite can withstand heavy vibrations, which is typical during the processing of LCD panel inspection. As a result, it can ensure that the components remain stable and secure at all times, leading to high accuracy in the inspection.

Dimensional Stability

Another advantage of using granite is its exceptional dimensional stability. This means that granite is relatively immune to changes in temperature and humidity. This property is crucial in LCD panel inspection devices as even minor changes in temperature or humidity could significantly impact the accuracy of the device.

Granite doesn't contract or expand when subjected to varying temperatures, which means that its dimensions and shape always remain constant. This helps to ensure the accuracy of the device, allowing it to consistently produce high-quality inspection results.

Vibration Dampening

Granite has a naturally high degree of vibration dampening, which means that it can absorb vibrations that would otherwise interfere with the LCD panel inspection process. This is a significant advantage over metal as it helps to reduce the amount of noise that the device generates, leading to a more reliable inspection.

This property is particularly advantageous in an industrial environment where there is a high degree of noise and vibrations. Granite components can help to reduce noise pollution and improve the working environment for operators.

Improved Results

Finally, because granite is more stable than metal, it has the potential to produce more accurate inspection results. The reduced vibrations and increased stability can minimize measurement errors, thus increasing the precision of the device.

The Bottom Line

In summary, using granite for components in LCD panel inspection devices has several advantages over metal. Granite is far more durable, dimensionally stable, and has better vibration damping properties than metal. Choosing granite over metal can result in a longer lifespan for the device, more reliable and accurate inspection results, and a better working environment for operators.

As technology advances, the demand for better, more accurate, and reliable LCD panel inspection devices will only continue to grow. Choosing the right material for the components is a critical step in meeting these demands, and granite proves to be the ideal choice.

Post time: Oct-27-2023