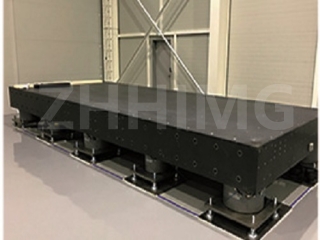

When it comes to manufacturing wafer processing products, the base of the machine is as important as any other part. A strong, stable base is essential to ensure the accuracy of the machining process and to prevent any damage to sensitive components. While metal is a common choice for machine bases, granite is an increasingly popular alternative due to its unique properties. Here are some of the reasons why granite may be a better choice than metal for a granite machine base.

1. Stability and stiffness

Granite has a much higher density and stiffness than most metals, which means it has a better resistance to vibrations and movement. This is particularly important in wafer machining applications, where even small vibrations or movements can cause inaccuracies or defects in the finished products. Granite's stability and stiffness make it an ideal material for machine bases that require the utmost precision.

2. Resistance to temperature changes

One of the main advantages of granite over metals is its ability to withstand temperature changes and variations. This is important in wafer processing, where the temperature can fluctuate significantly during the manufacturing process. Unlike metals that can expand or contract with temperature changes, granite maintains its shape and size, ensuring reliable and consistent performance.

3. Durability and longevity

Granite is one of the hardest materials available, making it extremely resistant to wear, tear, and damage. This makes it an ideal material for machine bases that need to withstand heavy loads or frequent use. Even after years of use, a granite machine base will maintain its stability, stiffness, and accuracy, providing consistent and reliable performance over time.

4. Non-magnetic properties

Unlike metals, granite is non-magnetic, which is essential in wafer processing applications where magnetic interference can cause significant damage. A granite machine base ensures that magnetic fields are not present in the machining environment, which reduces the risk of interference and improves the accuracy of the machining process.

5. Easy to maintain and clean

Granite is easy to clean and maintain, which is essential in wafer processing applications where cleanliness is critical. Unlike metals, granite does not corrode, rust, or tarnish, which means it requires minimal maintenance and cleaning. Regular cleaning and maintenance will ensure that the machine performs optimally, providing accurate and reliable machining over a long lifespan.

In conclusion, while metals have been the traditional choice for machine bases, granite is an increasingly popular alternative due to its unique properties. Choosing a granite machine base over a metal one can have significant advantages, including stability, stiffness, resistance to temperature changes, durability, non-magnetic properties, and ease of maintenance. If accuracy, reliability, and longevity are paramount in your wafer processing application, granite is definitely worth considering.

Post time: Nov-07-2023