When it comes to Precision Apparatus assembly products, choosing the right material is crucial. Among the various materials available, granite has gained significant popularity over the years. It is a natural material that is widely used in engineering and manufacturing. In this article, we will discuss the reasons why you should choose granite instead of metal for Precision Apparatus assembly products.

1. High stability and rigidity

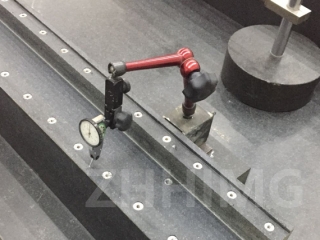

Granite is known for its high stability and rigidity, making it an excellent material for Precision Apparatus assembly products. This is because granite has a homogeneous structure, which means that it has uniform properties throughout the material. It also has a low coefficient of thermal expansion, which means that it does not change its dimensions significantly under temperature changes. These properties make granite an ideal choice for high-precision applications that require dimensional stability.

2. Vibration dampening

Granite has excellent vibration dampening capabilities, which is critical for Precision Apparatus assembly products. Vibration can adversely affect precision instruments by introducing unwanted movement and noise, which can impact the accuracy of measurements. Granite's vibration dampening capabilities help to minimize vibrations, ensuring that measurements are precise and accurate.

3. Resistant to corrosion

Unlike metal, granite is resistant to corrosion, making it an ideal choice for applications that require resistance to chemical substances. Metal is susceptible to corrosion, which can weaken its structural integrity and compromise the accuracy of measurements. Granite's resistance to corrosion means that it is durable and long-lasting, making it an excellent investment for Precision Apparatus assembly products.

4. Easy to clean and maintain

Granite is easy to clean and maintain, which is essential for Precision Apparatus assembly products. Precision instruments require a clean and dust-free environment to ensure their accuracy and longevity. Granite's smooth and non-porous surface makes it easy to clean and maintain, ensuring that the instruments remain clean and free of contaminants.

5. Aesthetically pleasing

Aside from its technical properties, granite is also aesthetically pleasing. It has a natural beauty that adds to the visual appeal of Precision Apparatus assembly products. Granite comes in a variety of colors and patterns, making it possible to create unique and visually appealing products.

In conclusion, granite is an excellent choice for Precision Apparatus assembly products. Its stability, vibration dampening capabilities, resistance to corrosion, easy maintenance, and aesthetic appeal make it an ideal material for high-precision applications. So, if you are looking for a material that can deliver accuracy, stability, and durability, then granite is the way to go.

Post time: Dec-22-2023