Granite has been used for centuries as a stable and reliable material for precision machinery. It is common to find granite in large precision machine bases or in precision surface plates. In more recent times, granite has also become a popular material for precision black granite parts products. These products range from granite blocks and cylinders to granite angle plates and granite v-blocks.

There are several reasons why granite is preferred over metal for these precision products. In this article, we will discuss the advantages of using granite in precision parts products.

1. Stability: Granite is an extremely dense and stable material. It does not expand or contract significantly with temperature changes. This makes it an ideal material for precision parts that require stability and accuracy over a wide range of temperatures. In contrast, metals tend to expand and contract with temperature changes.

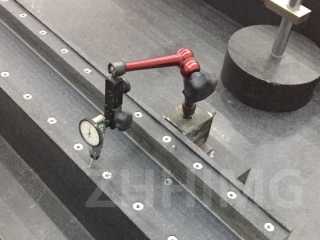

2. High precision: Granite is an exceptionally hard and rigid material. It is able to maintain its shape and accuracy even under heavy loads. This strength and rigidity make it ideal for precision parts that require high accuracy and tight tolerances. Granite can be precision-machined to extremely precise dimensions, even down to the sub-micron level.

3. Wear resistance: Granite is an extremely hard material, making it resistant to wear and abrasion. This means that it is able to maintain its accuracy and dimensional stability over a long period of time. This makes it ideal for tools and machines that need to perform consistently over a long period of time. In contrast, metals tend to wear down over time due to friction and abrasion.

4. Corrosion resistance: Granite is also highly resistant to corrosion. It does not rust or corrode like metals do, which ensures that the precision components made from granite will last for a long time. This is important for products that are exposed to moisture or chemicals, as exposure to these elements can cause metals to corrode or degrade over time.

5. Aesthetic appeal: Finally, granite has an inherent aesthetic appeal that makes it an ideal material for products where appearance is important. Its natural beauty and unique patterns and colors make it a popular choice for precision parts products where a high degree of craftsmanship and attention to detail is required.

In conclusion, while metals have been used for precision products for many years, granite has several advantages over metal that make it an ideal choice for precision black granite parts products. The stability, precision, wear resistance, corrosion resistance, and aesthetic appeal of granite make it a superior choice for precision parts products where accuracy and attention to detail are essential.

Post time: Jan-25-2024