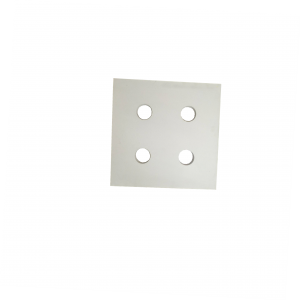

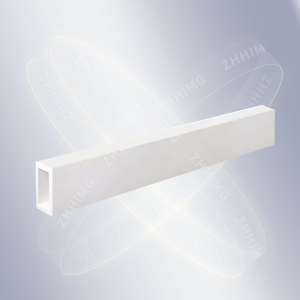

Precision Ceramic Gauge

Compared with metal gauges and marble gauges, ceramic gauges have high rigidity, high hardness, high density, low thermal expansion, and small deflection caused by their own weight, which has excellent wear resistance. It has high hardness and excellent wear resistance. Due to the small thermal expansion coefficient, the deformation caused by temperature changes is small, and it is not easily affected by the measurement environment. High stability is the best choice for ultra-precision gauges.

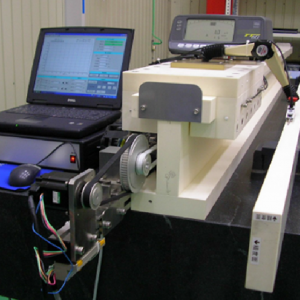

For semiconductor, precision optics, micro machining, ultra-precision machine tools, testing and precision and ultra-precision equipment, machine tool calibration benchmarks, Machine tool assembly accuracy, testing and calibration Measure the motion accuracy (straightness/perpendicularity/flatness/parallelism) of 3D measuring machines, etc.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM,metrology... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Al2O3, SiC,SiN... |

|

Color |

Black,white... |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, Field mai |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

precision ceramic, fine ceramic |

Certification |

CE, GS, ISO, SGS, TUV... |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT... |

Drawings’ format |

CAD; STEP; PDF... |

☛Temperature stability: "Coefficient of Thermal Expansion" The thermal expansion coefficient of granite and industrial ceramics is only about 1/4 of that of aluminum alloy materials and 1/2 of that of steel.

☛Thermal compatibility: At present, the equipment of aluminum alloy (beam and main shaft), the workbench is mostly made of granite;

☛Anti-aging stability: After the aluminum alloy material is formed, there is a large internal stress in the component,

☛"Rigidity/mass ratio" parameter: industrial ceramics is 4 times that of aluminum alloy materials. That is: when the rigidity is the same, the industrial ceramic only needs 1/4 of the weight;

☛Corrosion resistance: non-metallic materials do not rust at all, and the inner and outer materials are the same (non-plated), which is easy to maintain.

Obviously, compared with industrial ceramics, the good dynamic performance of aluminum alloy material equipment is obtained by "sacrificing" rigidity.

In addition to the above reasons, forming methods such as aluminum alloy extrusion are lower than non-metallic materials in terms of forming accuracy.

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

Material Analysis (Physical Properties):

1. Granite Material from Mines

1. Granite Material from Mines

2. Ceramic Material

3. Mineral Casting

4. Precision Metal

5. Precision Glass

6. UHPC

7. Carbon fiber