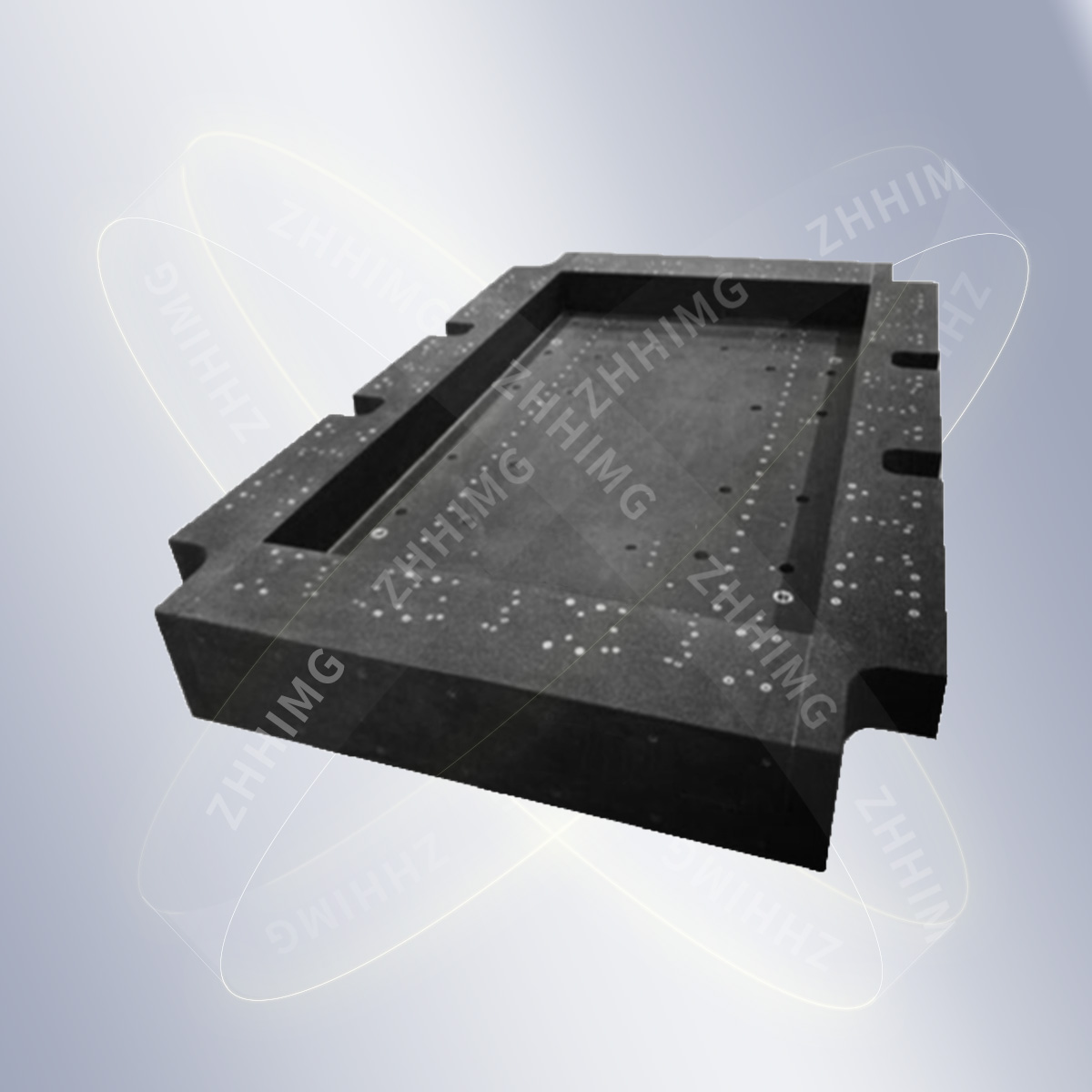

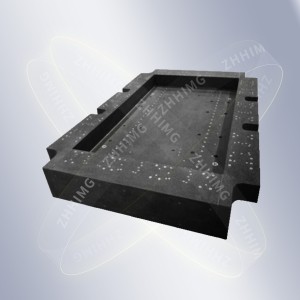

Precision Granite for Semiconductor

Granite is an optimum material for precision machinery – from co-ordinate measuring equipment to general machine construction with honing, grinding and milling. Depending on the respective requirements, various types of granite, e.g.Jinan Black Granite, Indian Black Granite...are available.

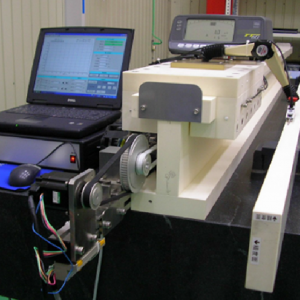

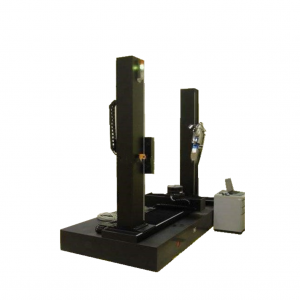

We can also deliver to customers the measuring and test benches we use for our quality assurance.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Black Granite |

|

Color |

Black / Grade 1 |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈3.05g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, Field mai |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Granite Machine Base; Granite Mechanical Components; Granite Machine Parts; Precision Granite |

Certification |

CE, GS, ISO, SGS, TUV... |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT... |

Drawings’ format |

CAD; STEP; PDF... |

1. Effectively ensure the overall accuracy of the machine tool: granite machine bed, gantry, machine bed and other machine tool components are all manufactured by manual grinding under constant temperature and humidity. The straightness, flatness, parallelism and verticality can reach 0.0015mm/1000mm*1000mm

2.The Shore hardness is 108, which is 3 times that of cast iron, and the wear resistance is 20 times that of cast iron. The compressive strength is 2290-3750 kg/cm2. It is resistant to abrasion, acid, alkali, and corrosion, and does not deform under heavy pressure.

3.The coefficient of linear expansion is one-third of that of cast iron, and the thermal stability is 20 times that of cast iron. Its thermal deformation is very little.

4.The damping coefficient (the ability to prevent and absorb vibration) is 10 times larger than that of cast iron, and it is all solid, with good ability of shock absorption. From experiments, it has proved that the use of granite machine bed, gantry, machine bed and other machine tools can increase the surface accuracy of workpieces by 30%, and the tool durability can be improved by 37%.

5.Unlike metallic materials, granite doesn’t have plastic deformation nor magnetic reaction. Granite has good rigidity and physical properties.

6.Granite doesn’t rust. It’s easy to maintain and has longer service life. Stone processing has low energy consumption, no pollution. The material is derived from nature. It is eco-friendly and has high social benefits.

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

Material Analysis (Physical Properties):

1. Granite Material from Mines

1. Granite Material from Mines

2. Ceramic Material

3. Mineral Casting

4. Precision Metal

5. Precision Glass

6. UHPC

7. Carbon fiber