Resurfacing

Precision components and measuring tools will wear out during use, resulting in accuracy problems. These small wear points are usually the result of continuous sliding of parts and/or measuring tools along the surface of the granite slab. This requires us to calibrate it. Especially products like precision granite components and measuring tools, precision ceramic components and measuring tools.

If it is a small product such as a precision measuring tool, it is better to say, because the measuring tool is small in size and easy to calibrate and repair, it can be sent to the relevant laboratory for repair; and the cost of repurchasing is not high.

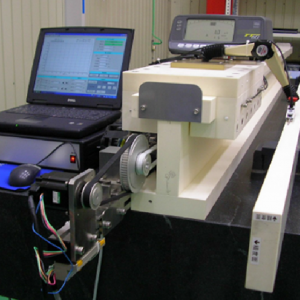

However, the super-large equipment (composed of precision granite components, ceramic components or precision metal components) used by some companies is not convenient to send to relevant laboratories for calibration and repair, which requires qualified suppliers to come to repair . Because the precision equipment required is more expensive, such as laser interferometers, electronic level gauges, dial indicators and other related instruments. At present, the quality and functions of Renishaw's laser interferometers in the world are at the top level in the world. The level gauges produced by Swiss wyler are widely used and reliable in quality. Instruments such as dial gauges produced by mahr and mitutoyo are also at the world's leading level. If you can not measure it, you can not make it.

According to local inspection standards, such as DIN 876 Standard, Federal Specifications GGG-P-463c, etc., each panel must pass repeatability and overall flatness tests to obtain legal certification. The allowable tolerance of the panel is defined by its size and grade.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

Material Analysis (Physical Properties):

1. Granite Material from Mines

1. Granite Material from Mines

2. Ceramic Material

3. Mineral Casting

4. Precision Metal

5. Precision Glass

6. UHPC

7. Carbon fiber